|

|

|

|

New PLC Cable and

Debouncer Feature for Basler scout and pilot Cameras

Basler

scout and Basler

pilot cameras are employed in many industrial applications. They are

used for automation tasks such as pick and place, separation, and

quality control. For ease of integration, each camera provides a

powerful digital I/O interface to communicate with external devices. The

camera interface can be used with different voltage ranges including TTL

(0-5 V) and CMOS (0-3.3 V).

PLC Cable

Because

the typical PLC voltage level is from 0 to 24 volts, when the cameras

are in a PLC environment, use of the I/O interface requires particular

attention. To adapt the voltage level of a PLC signal to the voltage

level of the camera I/O, a special PLC cable is required. The cable

includes an electronic device that adapts the PLC voltage level and also

protects the camera against negative voltage peaks. Because

the typical PLC voltage level is from 0 to 24 volts, when the cameras

are in a PLC environment, use of the I/O interface requires particular

attention. To adapt the voltage level of a PLC signal to the voltage

level of the camera I/O, a special PLC cable is required. The cable

includes an electronic device that adapts the PLC voltage level and also

protects the camera against negative voltage peaks.The PLC cable must be used whenever the camera is used in a PLC application. The cable is available in two different versions – as a three meter cable (Hirose connector - open end) and as a ten meter cable (Hirose connector – open end).

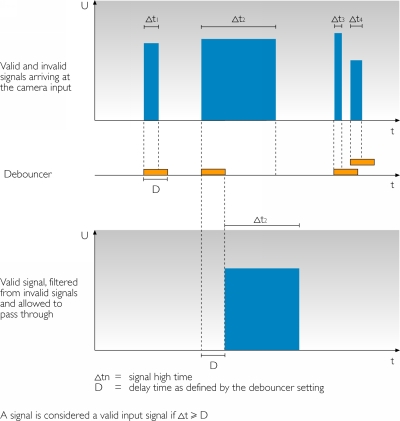

Debouncer Feature

To enhance the operational reliability of Basler Basler scout and Basler pilot cameras in industrial environments, a new debouncer feature has been introduced. The feature separates short invalid signals applied to the camera's input lines from longer valid signals. Short invalid signals are filtered out and longer signals are recognized as valid trigger signals.

The debouncer feature must be used whenever a Basler scout or pilot camera is used in an industrial environment and is triggered by an external signal. With the factory default settings, the debouncer feature is disabled. Please refer to your camera’s user manual for information about using the debouncer feature. The debouncer feature is included in all Basler scout and pilot cameras with firmware version 3.0 or higher. |

The newest added feature is dust and dirt protection for the sensor enclosure. Preventing dust and dirt from entering the sensor area is a tough job. First, there must be no dust in the air during production of the cameras, and Basler’s production process has been updated to eliminate any dust in the air. Next, each camera must operate for months or years in often harsh industrial conditions, and this demands appropriate dust protection inside the camera. To ensure that Basler scout and pioneer cameras will have the appropriate level of dust protection, they are tested at least two times during production. The first test is implemented as part the focal length adjustment procedure and the second test is performed as a final check. Once the tests are passed, the lens mount threads are covered with a secure cap. All production steps are performed in a clean room environment since the end of 2007. This prevents small particles that can influence image quality or affect image processing results from entering the cameras during production. |

Dusty sensor |

In extreme cases, dust or dirt that enters a camera can cause shadows or even stop some pixels from receiving any light at all. The remedy in this situation would be to dismount the camera from the machine and clean the surface of the imaging sensor. For cameras with a fixed IR-cut filter, dust inside of the camera would make repair of that camera at the vendor’s facility a necessity. All of this represents an annoying effort for the end user and worries both OEMs and system integrators. |

Clean sensor |

The

new dust protection technology used in Basler cameras separates the sensor

from the camera's core board and other electronics. This is accomplished

by using several special lip-seals to form a sensor enclosure extending

from the sensor board to the front plate of the camera. For cameras

equipped with an IR-cut filter, the filter screws into the lens adapter

threads and completely seals the sensor enclosure. This dust and dirt protection is already being applied to all Basler scout cameras and application to the Basler pilot series has started. Full conversion of all pilot models will be finished in June 2008. |

| © 1993-2008 Total Turnkey Solutions. | |